Capabilities

At Chaparral Technologies, Inc., we pride ourselves on being a leading Manufacturer’s Representative Agency that has mastered the art and science of precision mechanical component production. Our capabilities extend to a wide range of processes, including metal casting, rapid prototyping, metal forging, CNC machining, metal injection molding, and 3D printing services, all designed to meet our client’s most exacting requirements.

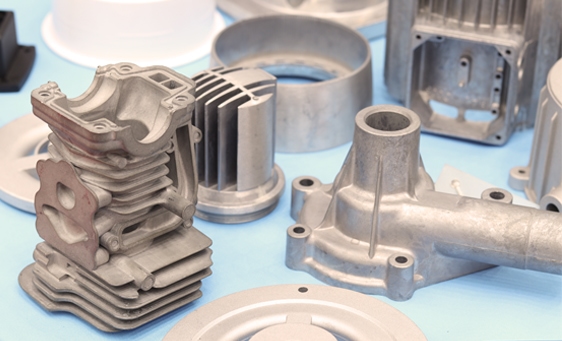

Metal Casting: Versatile and Reliable Solutions

Metal casting, a central pillar of our capabilities at Chaparral Technologies. From simple to complex geometries, our casting process takes the versatility of molten metal, solidifies it in molds, and gives birth to components that are both functional and aesthetically pleasing.

We cater to an array of casting requirements, producing components that weigh less than a pound to several tons. Economically viable for both singular prototype parts and multiple unit production, our expertise allows us to select the optimal casting method based on your specific needs.

The casting process entails five crucial stages: molding, pouring, solidification, mold removal, and secondary operations such as trimming and painting. We work with various casting techniques, including sand casting, permanent mold processes, ceramic processes, and rapid prototyping, tailoring the method to the project.

Innovative and forward-thinking, we also leverage rapid prototyping in our casting process to swiftly create functional test parts from CAD data. In essence, our metal casting capability is your key to unlocking unparalleled design flexibility, efficiency, and reliability in manufacturing.

Metal Forging: Unmatched Strength and Durability

As a premier Manufacturer’s Representative Agency, Chaparral Technologies offers comprehensive metal forging services. Forging, a process that compresses and shapes metals, has been around since the Mesopotamians first used it to create tools and weapons. Over time, modern equipment and methods have made this process more efficient, versatile, and reliable.

We collaborate with experienced manufacturers capable of delivering high-quality forged components. Our network invests in advanced technology to provide parts ranging from a few pounds to over 70,000 pounds, delivered as raw forgings or machined complete products.

The metal forging process can be divided into two main types: hot and cold forging. Hot forging involves heating the metal to its recrystallization temperature, allowing for easier shaping due to increased flexibility. On the other hand, cold forging is performed at room temperature, offering increased versatility but requiring more powerful equipment.

Several sub-processes, including open die forging, closed die forging, and seamless rolled ring forging, further diversify our forging capabilities. These methods cater to specific needs, from creating intricate shapes to forming circular metal parts.

The robust nature of metal forging has allowed it to find applications in various industries, such as automotive, agriculture, and oil production. From wheel spindles and axles for cars to valves and reducers for oil operations, our forging services cater to a wide spectrum of industrial uses.

In essence, our metal forging capability at Chaparral Technologies is your gateway to robust, high-quality, and durable metal components that underpin the growth of your business.

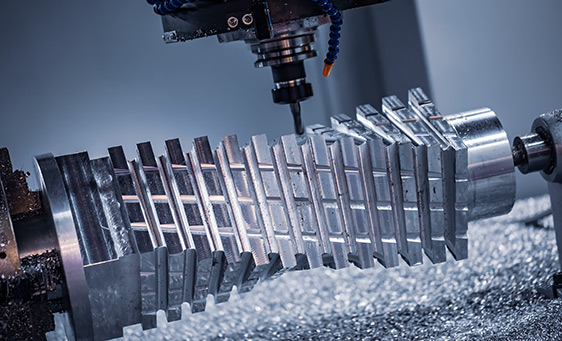

Precision CNC Machining: Delivering Precise, High-Quality Components

At Chaparral Technologies, we take pride in our robust precision CNC machining capabilities, bolstering the backbone of industries ranging from medical to telecommunications and aerospace to commercial sectors. Our advanced CNC machining, along with conventional methods, allows us to produce components of exceptional accuracy and quality.

We cater to projects of all scales, handling operations from micro-machining to the processing of several tons. Our expertise spans across a plethora of materials, including various metals and plastics, ensuring we meet your specific needs with precision.

Our CNC machining services encompass a wide array of processes. Whether you need a prototype or production machining, we deliver excellence in every component we create. Our multi-axis automatic machining and screw machining capabilities enable us to tackle complex geometries and designs with ease.

We also offer Swiss screw machining, known for its high precision and ability to produce small, intricate parts. At Chaparral Technologies, precision CNC machining is not just a service – it’s a commitment to quality, accuracy, and customer satisfaction.

Expertise in Powdered Metals: Pioneering Solutions for Your Metallurgy Needs

Powder metallurgy is a cornerstone of Chaparral Technologies’ manufacturing services. Celebrating over a century of existence, this technique heats compacted metal powders to near-melting points, forming high-quality parts that adhere to exacting specifications.

Our expertise in powder metallurgy encompasses two key technologies – conventional press-and-sinter processes and the advanced metal injection molding (MIM) process. These techniques allow us to fabricate both semi-dense and fully dense components with unparalleled accuracy and consistency.

Metal injection molding presents a manufacturing capability for producing intricate shapes in large quantities. Utilizing fine metal powders mixed with a binder, we mold these into the desired shapes. Post-molding, the binder is extracted, and the part is sintered in a controlled atmosphere furnace. Metal injection molding offers the advantage of producing complex parts equivalent to wrought materials with exceptional dimensional tolerance control.

The Press & Sinter process involves feeding custom-blended metal powders into a die, compacting them into the desired shape, and subsequently sintering them. This process yields parts with tight tolerances that often require little to no secondary machining operations. Our press-and-sinter services provide economical manufacturing solutions while maintaining high precision and quality.

At Chaparral Technologies, we aim to deliver optimal solutions for your powder metallurgy needs. Our unwavering commitment to quality and precision ensures your expectations are not just met but exceeded.

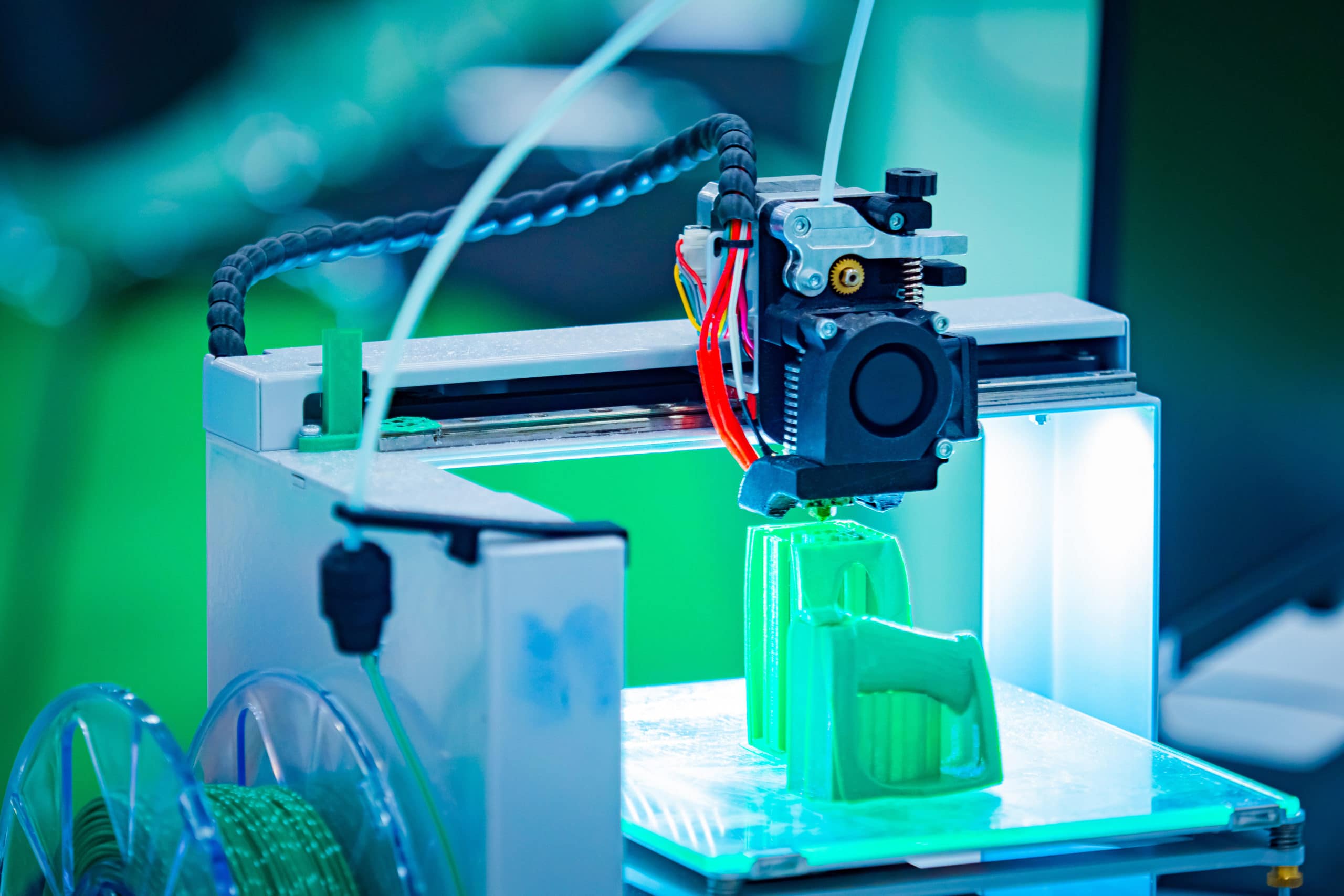

Cutting-Edge 3D Printing Services

Chaparral Technologies proudly offers a sophisticated 3D printing service, adeptly linking customer needs with the appropriate manufacturing capabilities. Our portfolio incorporates a variety of 3D printing techniques, each optimized for specific application requirements.

Direct Metal 3D Printing is an industrial-grade process that delivers durable, detailed parts rapidly. This technique sinters and compresses powdered metal layer by layer, resulting in the precise desired shape. Ideal for complex, intricate designs, it surpasses the capabilities of traditional manufacturing processes.

Stereolithography (SLA) quickly generates models, prototypes, and complex parts with detailed geometries. SLA utilizes a UV laser to deposit and heat a liquid thermoset resin, enabling high-quality, accurate, and detailed outcomes. Its versatility makes it a popular choice for form and fit testing parts and final-stage prototypes.

Selective Laser Sintering (SLS) creates solid 3D objects from powdered materials, transforming CAD files into tangible components. Suitable for intricate geometries with specific specifications, this technique forms solid structures by layering and sintering powderized materials.

At Chaparral Technologies, we’re committed to driving your vision into reality. With our global presence, we offer comprehensive 3D printing services, encompassing process and material selection, design for manufacturability, project management, value engineering, and continuous improvements.

Work With Us

Our goal at Chaparral Technologies, Inc., goes beyond merely providing services. We aim to build lasting relationships with our customers, driven by our dedication to offering integrated, customized solutions.

When you partner with Chaparral Technologies, you aren’t just getting a service provider; you’re getting a dedicated team of experts committed to your project’s success from start to finish. We invite you to experience the difference our comprehensive capabilities can make on your next project.

Don’t just take our word for it. Discover the difference that expertise, commitment, and cutting-edge technology can make for your project. Contact us today to discuss your needs and learn how Chaparral Technologies can help turn your ideas into reality.