Chaparral Technologies is a premier Manufacturer’s Representative Agency that can readily provide outsourcing solutions to numerous industries. We work with experienced manufacturers who you can rely on to deliver consistent high-quality components. Metal forging is one of many manufacturing processes we can help our customers source.

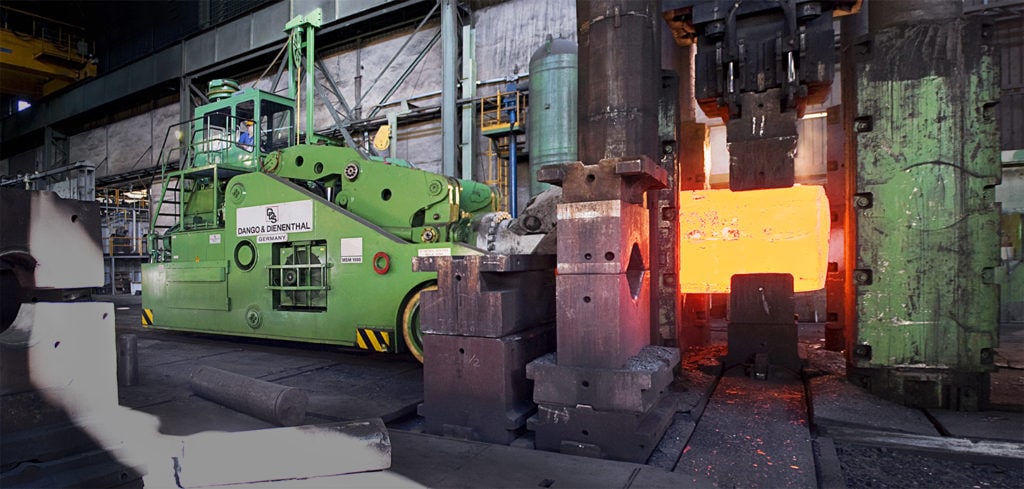

Our manufacturer network continuously invests in leading technology so they can provide high quality parts and assemblies. Our forging capabilities range from parts weighing a few pounds to parts weighing over 70,000 pounds. These parts can be provided to our customers as raw forgings or machined complete, ready to be assembled into their product. We strive to deliver customer success and satisfaction while nurturing our relationships with manufacturers, equipped with a wide range of capabilities to serve our clients better.

What is Forging?

Metal forging is a metalworking or shaping technique that deforms, compresses, and shapes metals to achieve a desired appearance or form. It has been around since the time of the Mesopotamians when the process was used to create tools and weapons.

Modern equipment and technical methods made the whole process faster, more durable, and more manageable. However, forging metal isn’t as simple as putting pressure on the material to achieve the perfect product. There are two types of forging to consider:

Hot Forging

In hot forging, the metal is heated up to its recrystallization temperature, which can reach up to 2,300 degrees Fahrenheit. Here, the main benefit is decreased energy needed to form the metal. Heating metal reduces its yield strength while increasing flexibility, making it easier to form or shape.

Cold Forging

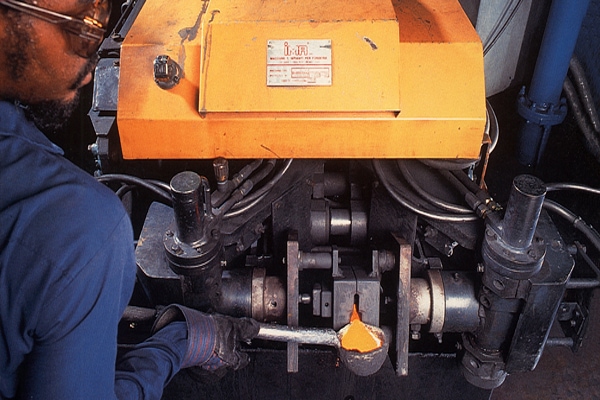

Cold forging metals are done at room temperature. It increases versatility in forging techniques, such as bending, coining, cold heading, extruding, and cold drawing. However, it requires more powerful equipment.