At Chaparral Technologies, we are a manufacturer’s representative agency that finds solutions to meet the changing needs of our clients. We invest in new technology and training for our team to deliver a broad range of manufacturing capabilities, including direct metal 3D printing.

Direct metal 3D printing fuses multiple layers of metal powder to form a metal part or prototype in seven days or less. This process delivers a component with the high strength and durability of metal while taking advantage of the design freedoms that come with 3D printing. Direct metal 3D printing allows us to deliver complex designs that are not achievable using CNC machining.

Our Direct Metal 3D Printing Capabilities

At Chaparral Technologies, our direct metal 3D printing capabilities allow us to meet a broad range of product requirements. We are capable of producing a product with the following specifications:

- Max Dimensions:

- 75mm in the longest direction.

- Layer Thickness:

- 35 um in z-direction, as layer thickness is 42 μm and we have close to 20% shrinkage during sintering.

- Tolerances:

- Serial Production: typically reach a dimensional tolerance of ± 0.5% of outer dimension and at best ± 50 μm from batch to batch.

- One-off jobs/Prototyping:, typically achieve tolerance of ± 2.0% or better.

- Minimum feature size:

- Wall Thickness: Dependent upon area and design but we recommend > 0.3 mm as a guideline.

- Holes: Larger than 0.2 mm as a guideline.

- Minimum part size: Larger than 1 x 1 x 3 mm.

Our capabilities include direct metal laser sintering, which uses a laser to fuse sections of metal powder from the ground up, creating a full-density part with superior mechanical properties. We also provide binder jetting, a popular and inexpensive method of metal 3D printing that relies on a binder agent to bind the metal powder in a 3-dimensional shape before it is placed into a furnace to sinter. Binder jetting is a quick and cost-effective method of producing parts in higher volumes. We work with various metals, including aluminum, maraging steel, stainless steel, and titanium.

Applications of Direct Metal 3D Printing

Various industries, such as defense, aerospace, robotics, consumer products, and more, rely on direct metal 3D printing to manufacture complex parts and tooling with excellent strength and durability. Specific applications for direct metal 3D printing include:

- Tool and die making

- Chemistry and petrochemistry

- Veterinary and medical devices

- Aerospace engines

- Food and pharmaceuticals

- Automotive parts

- Machine construction

Why Use Direct Metal 3D Printing?

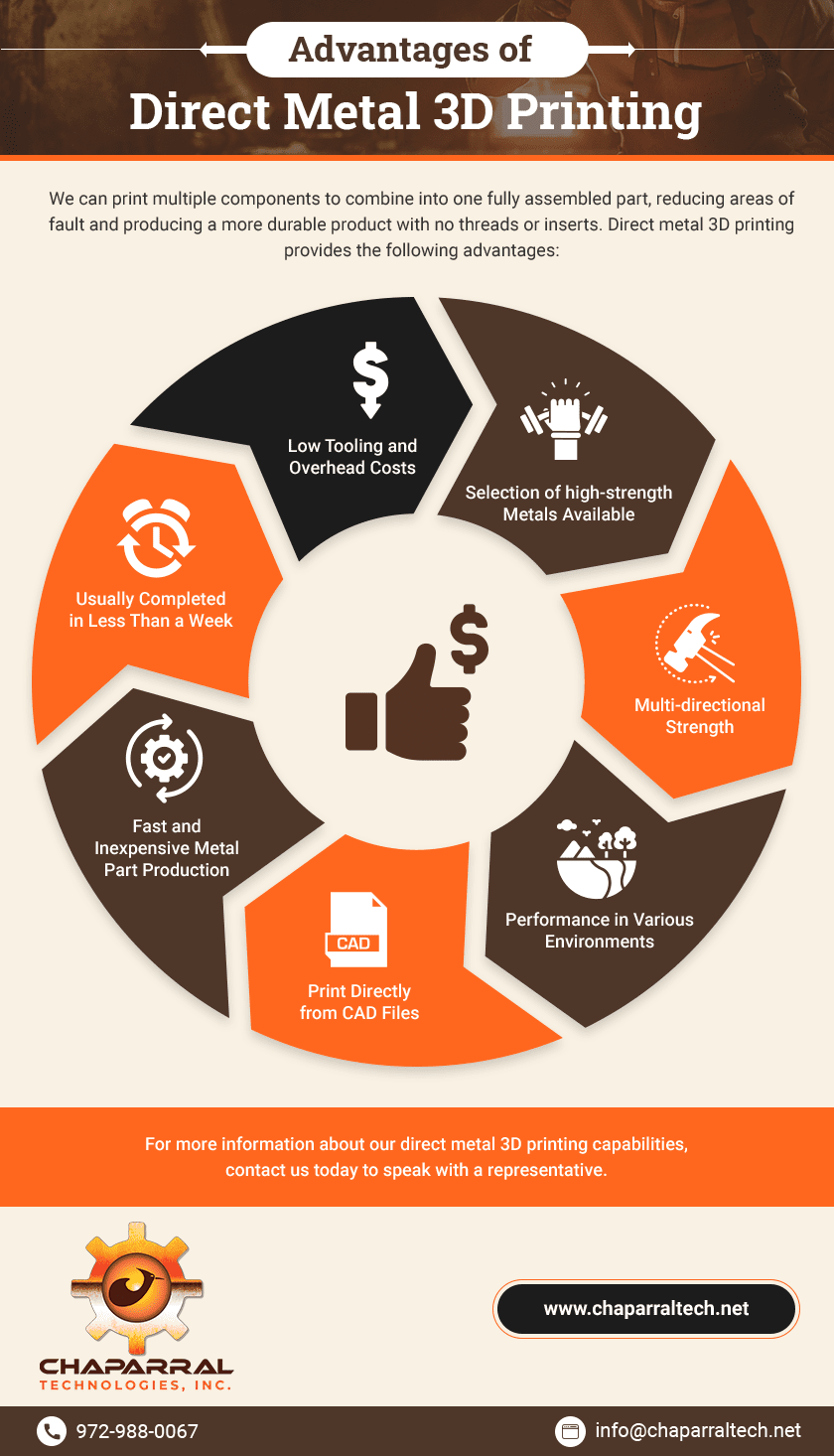

Direct metal 3D printing delivers various benefits. We can print multiple components to combine into one fully assembled part, reducing areas of fault and producing a more durable product with no threads or inserts. Direct metal 3D printing provides the following advantages:

- Selection of high-strength metals available

- Multi-directional strength

- Performance in various environments

- Print directly from CAD files

- Fast and inexpensive metal part production

- Usually completed in less than a week

- Low tooling and overhead costs

Direct Metal 3D Printing by Chaparral Technologies

Direct metal 3D printing is a method of producing high-strength and durable parts of various sizes and complexities. We use a range of materials to deliver products that meet the end user’s expectations and provide reliable performance in unforgiving environments. Metal 3D printing can take less than a week to complete at a lower cost than traditional machining methods.

Chaparral Technologies has over 50 years of experience and has built a presence around the globe. We have the technical expertise in direct metal 3D printing to deliver a product that meets your exact specifications. Our full-service solutions include process and material selection, design for manufacturability, advanced quality planning, project management, value engineering, and continuous improvements.

For more information about our direct metal 3D printing capabilities, contact us today to speak with a representative.