At Chaparral Technologies, we are a Manufacturer’s Representative capable of providing a wide range of services including additive manufacturing through 3D printing. We have relationships with dozens of service providers, allowing us to match your goals with the right manufacturing capabilities, materials, levels of customer support, and more to exceed your expectations with a solution for your exact needs.

Direct Metal 3D Printing

Direct Metal 3D Printing

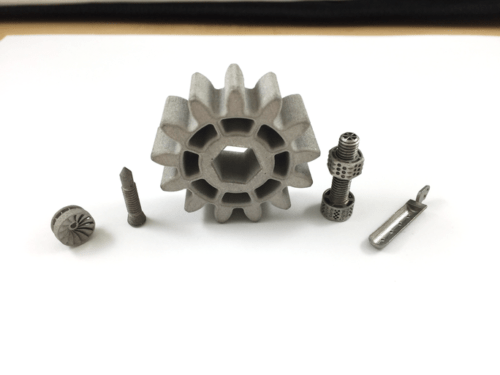

Direct metal 3D printing is an industrial production process that produces sturdy, detailed, and functional parts quickly. Printing services can create prototypes, final designs, and usable components. The printers work by sintering, or heating and compressing, the powdered metal workpiece layer by layer. After each layer, the machine deposits another layer of powder to be sintered and formed into the precise shape.

Once the part is constructed, the 3D printing machine brushes away the remaining powder and treats the surface to protect it and give the new metal surface a stronger finish with less internal stress. 3D printing processes allow for extremely complex, intricate, and fine designs that traditional manufacturing and machining processes can’t create.

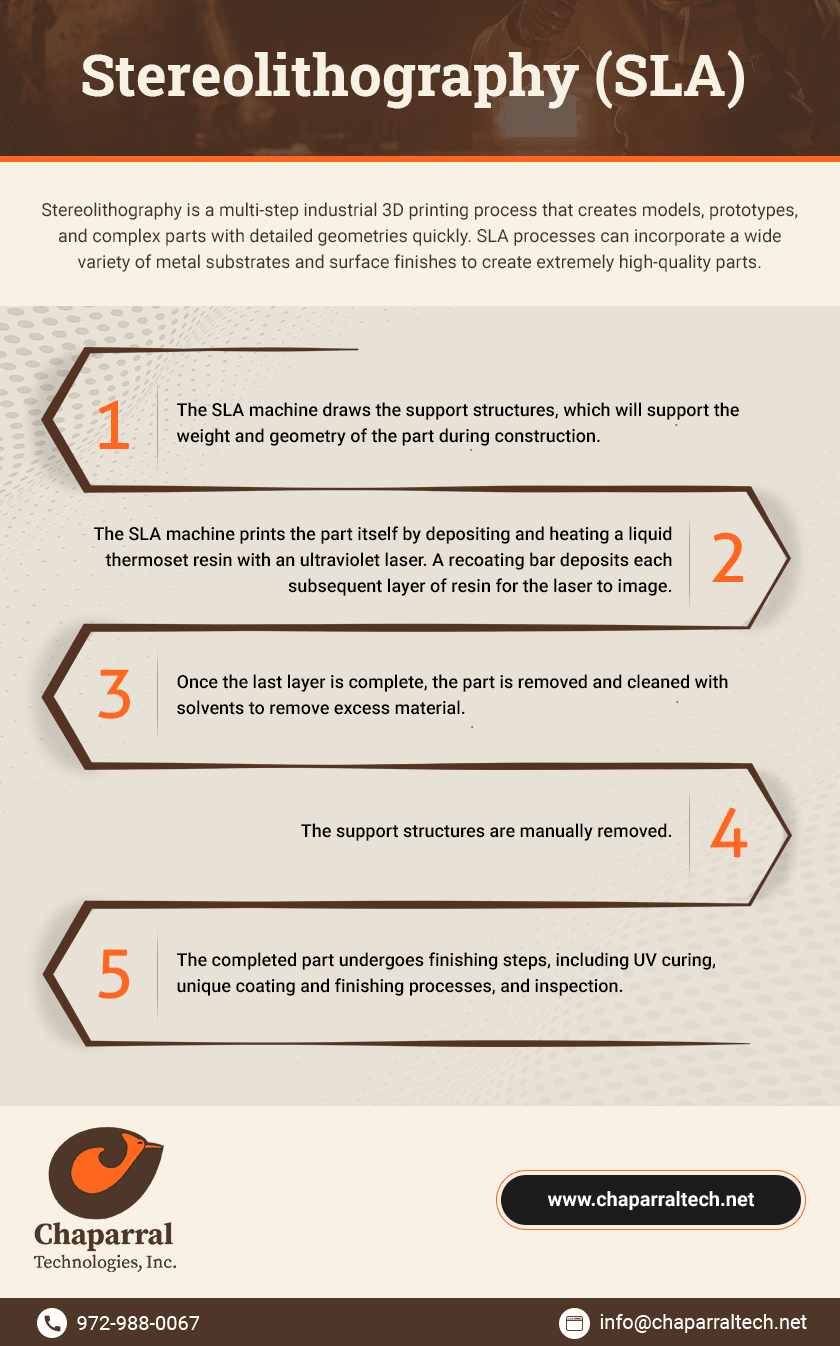

Stereolithography (SLA)

Stereolithography is a multi-step industrial 3D printing process that creates models, prototypes, and complex parts with detailed geometries quickly. SLA processes can incorporate a wide variety of metal substrates and surface finishes to create extremely high-quality parts. With certain materials, SLA models can be used as a pattern to cast any metal through the process of investment casting. SLA 3D printers allow for high levels of quality, accuracy, and extreme detail, making SLA a popular choice for creating fit and form testing parts and final-stage prototypes for cosmetic assessments.

SLA works by following these steps:

- The SLA machine draws the support structures, which will support the weight and geometry of the part during construction.

- The SLA machine prints the part itself by depositing and heating a liquid thermoset resin with an ultraviolet laser. A recoating bar deposits each subsequent layer of resin for the laser to image.

- Once the last layer is complete, the part is removed and cleaned with solvents to remove excess material.

- The support structures are manually removed.

- The completed part undergoes finishing steps, including UV curing, unique coating and finishing processes, and inspection.

Selective Laser Sintering

provider that is just right for your next project. Our full-service solutions include:

Sintering is the process of heating powderized plastics, glass, or ceramic to solidify it into precise shapes. Many modern 3D printing processes use selective laser sintering to create solid 3D objects with intricate geometries and very particular specifications.

To begin, selective laser sintering 3D machines convert CAD design files into .STL files that the machine can read as a precise set of instructions. Next, a thin layer of the powderized material is

deposited in the SLS machine’s chamber on the build platform where the laser heats it until it forms into a solid. The laser pulses intermittently and only along the cross-sectional surface of the shape. Once the layer is complete, the platform drops, a new layer of powder is dispersed across the platform, and the next cross-sectional layer is sintered. This continues — building the product in increments as small as 0.1mm high — until the part is complete.

Choose Chaparral Technologies to Support Your 3D Printing Needs

At Chaparral Technologies, we match each of our clients to service providers with the right technologies and capabilities. We have over 50 years of experience and a global presence, so we can find the service

Process and material selection

- Design for manufacturability

- Advance quality planning

- Project management

- Value engineering

- Continuous improvements

For more information, or to learn more about our 3D printing services, contact us today.

Direct Metal 3D

Direct Metal 3D